More than 30 years making structural repairs.

It’s awfully considerate of you to take a moment to visit our website. We are a company with more than 30 years dedicated to making Structural Repairs and Modifications in the Aviation Industry. We provide FAA DER Services and act as Advisors and Consultants for Maintenance Programs on various aircraft models including Douglas, Boeing, Airbus, Bombardier, Cessna, Lockheed, deHavilland, Fairchild, and Antonov.

We have a very extensive background with satisfied customers. Please take a few seconds to let us show you who we are.

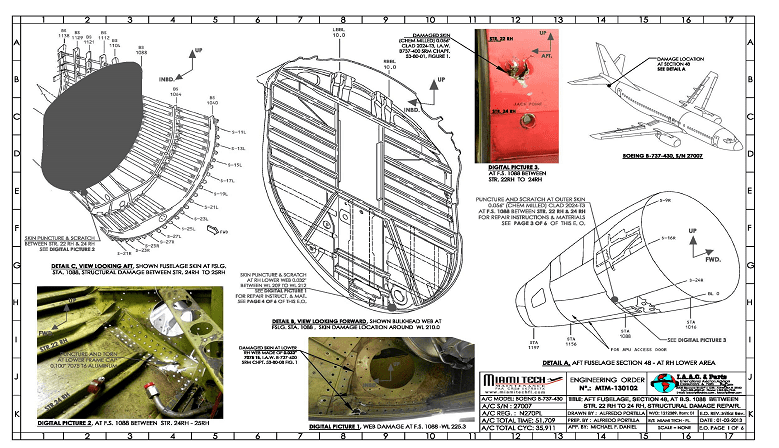

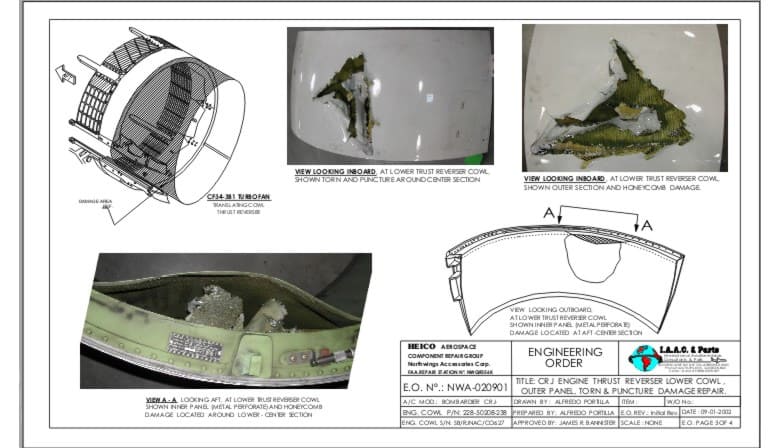

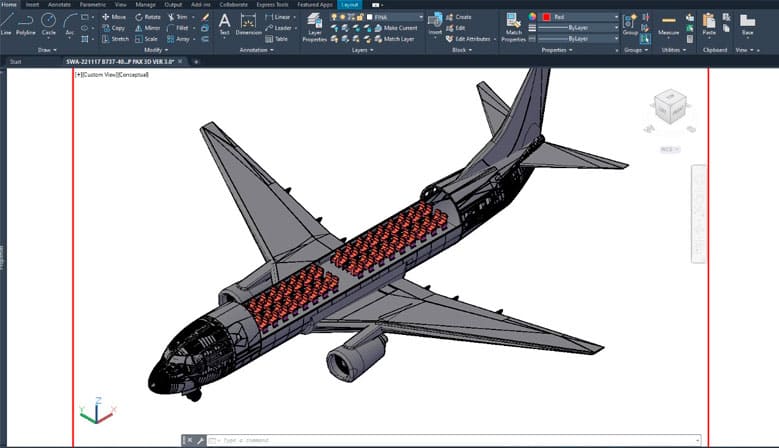

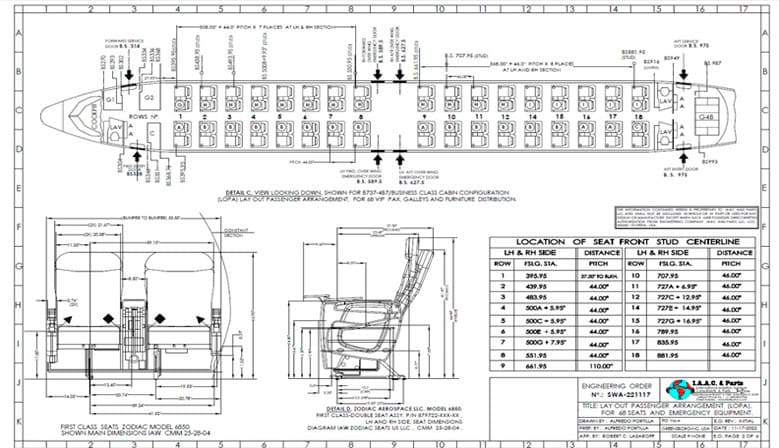

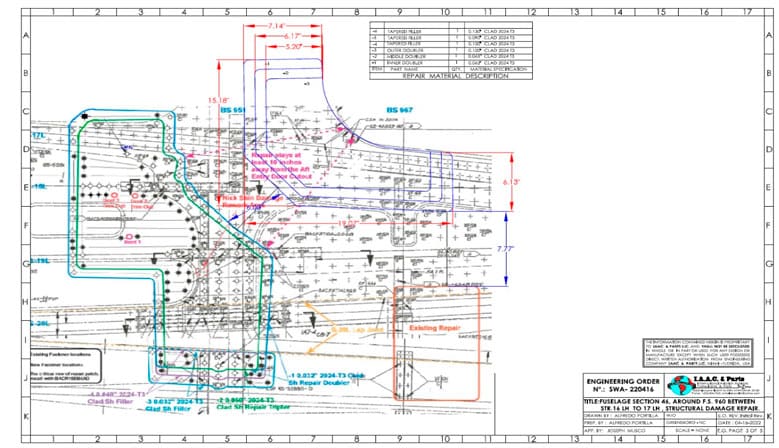

AIRCRAFT STRUCTURAL REPAIRS

Structural repairs are made to aircraft that have sustained damage to the structure (i.e., external skin, stringers, formers, bulkheads, etc.) There are several ways an aircraft structure can be damaged. It is usually caused by ground service equipment, maintenance stands, bird strikes, or lightning strikes.

Although the cause of an airplane accident has never been attributed to properly applied repairs using the original repair data, repairs may be of concern as time-in-service increases for the following reasons:

- As airplanes age, both the number and age of the existing repairs increase.

- Along with this increase is the possibility of unforeseen repair interaction, autogenous failure, or other damage occurring in the repaired area.

- The continued operational safety of these airplanes depends primarily on a satisfactory maintenance program (inspections conducted at the right time, in the right place, using the most appropriate technique).

- To develop this program, a damage-tolerance evaluation of repairs to flight-critical structures is essential.

- The longer an airplane is in service, the more important this evaluation and a subsequent inspection program become.

The damage-tolerance methodology has evolved gradually over the last 20 or more years.

- Some existing repairs described in the airplane manufacturers’ Structural Repair Manuals (SRM) were not designed to current standards.

- Repairs accomplished in accordance with the information contained in the early versions of the SRM’s may require additional inspections if evaluated using the current methodology.

- Because a regulatory requirement for damage-tolerance was not applied to airplane designs type certificated before 1978, the damage-tolerance characteristics of repairs may vary widely and are largely unknown.

(a) FAA shall approve design data in support of major repairs in accordance with:

- FAA Order 8110.4 Type Certification;

- FAA Order 8110.37, Designated Engineering Representative Guidance Handbook; FAA Order 8100.15, Organization Designation Authorization Procedures; and

- FAA Order 8300.16, Major Repair and Alteration Data Approval”.

- Minor repairs are made in accordance with “acceptable” data, in accordance with 14 CFR Part 43.

Alfredo Portilla

Aeronautic Engineer

- +1 305-3047963

- 20533 Biscayne Blvd. 4-1238 Aventura - Florida, 33180 USA

- iaacalfp@yahoo.com

- www.iaac-parts.com

Jesús Hirose M.

Representative for South America

- +51 981 517 842

- 20533 Biscayne Blvd. 4-1238 Aventura - Florida, 33180 USA

- capitan_beto@hotmail.com

- www.iaac-parts.com